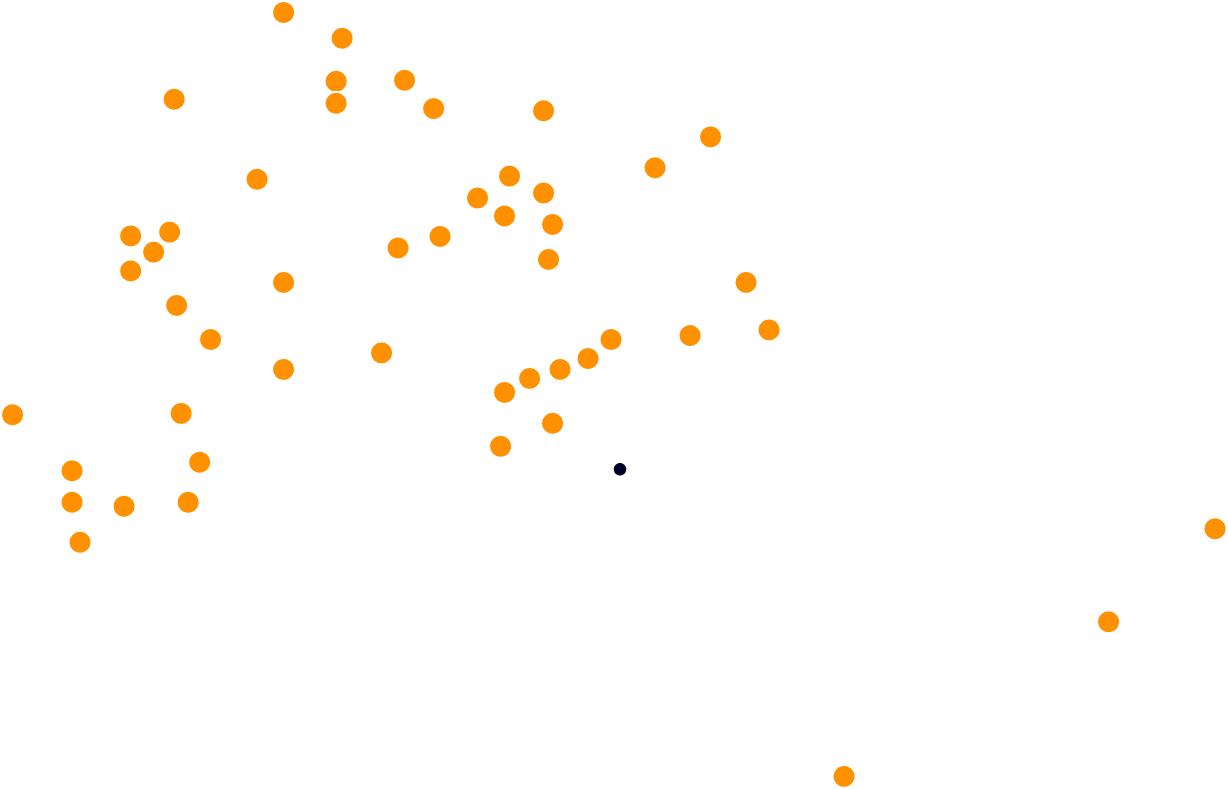

- Fully digital depot with 70,000 m² total area

- 5.5 km of electrified tracks in the outside area

- 6 maintenance tracks in the workshop hall

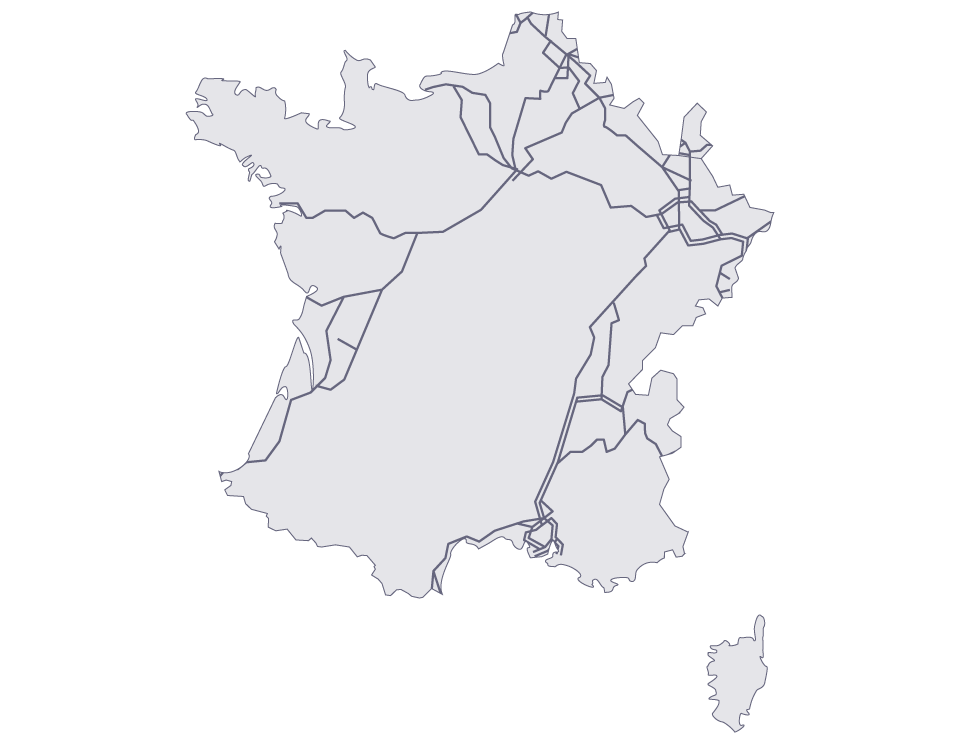

Highspeed

Highspeed Commuter Rail

Commuter Rail Locomotives

Locomotives

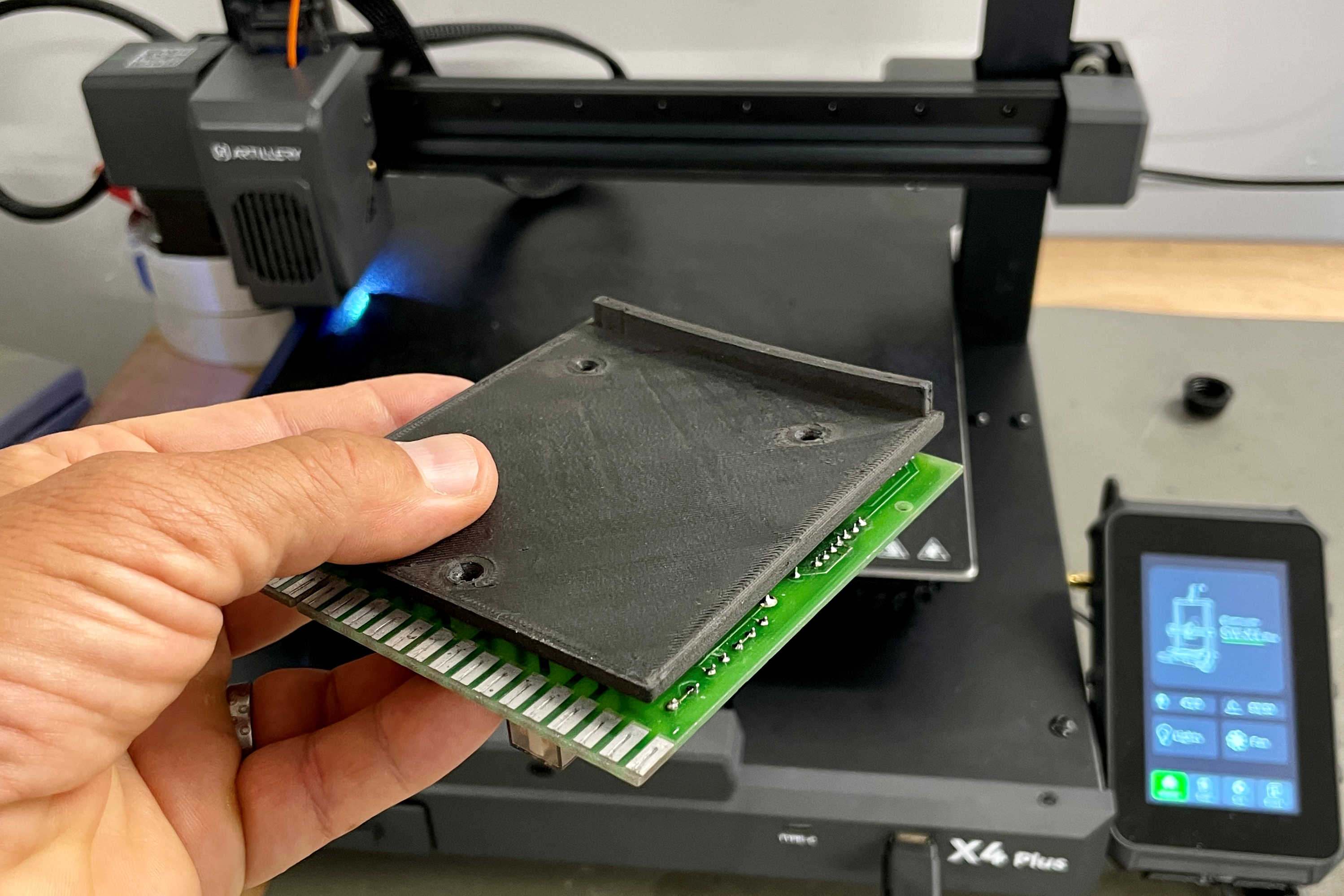

Rail Service Center / Digital depot

In a nutshell:

- Depot to be expanded to 87,550 m2

- New capacity for meeting growing demand

- 100% system availability thanks to digitalized depot operation

Siemens Mobility is expanding its service depot in Dortmund-Eving to 87,550 m2 to meet

the growing demand for rail services. Plans call for constructing an additional 12,300 m2

service hall with storage facility, offices, and workshops to handle the maintenance of trains

up to 400 meters long. Construction of the new building is scheduled to begin in 2024 and

be completed by 2026.

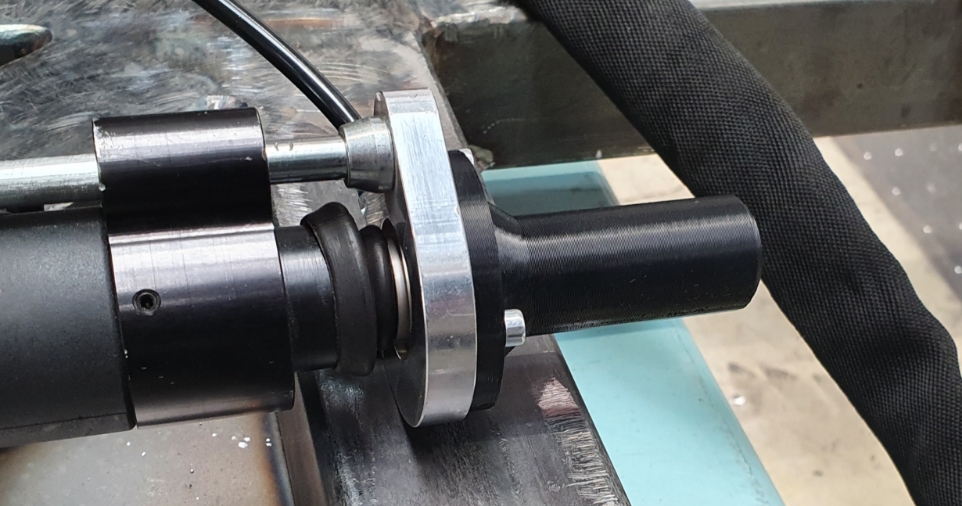

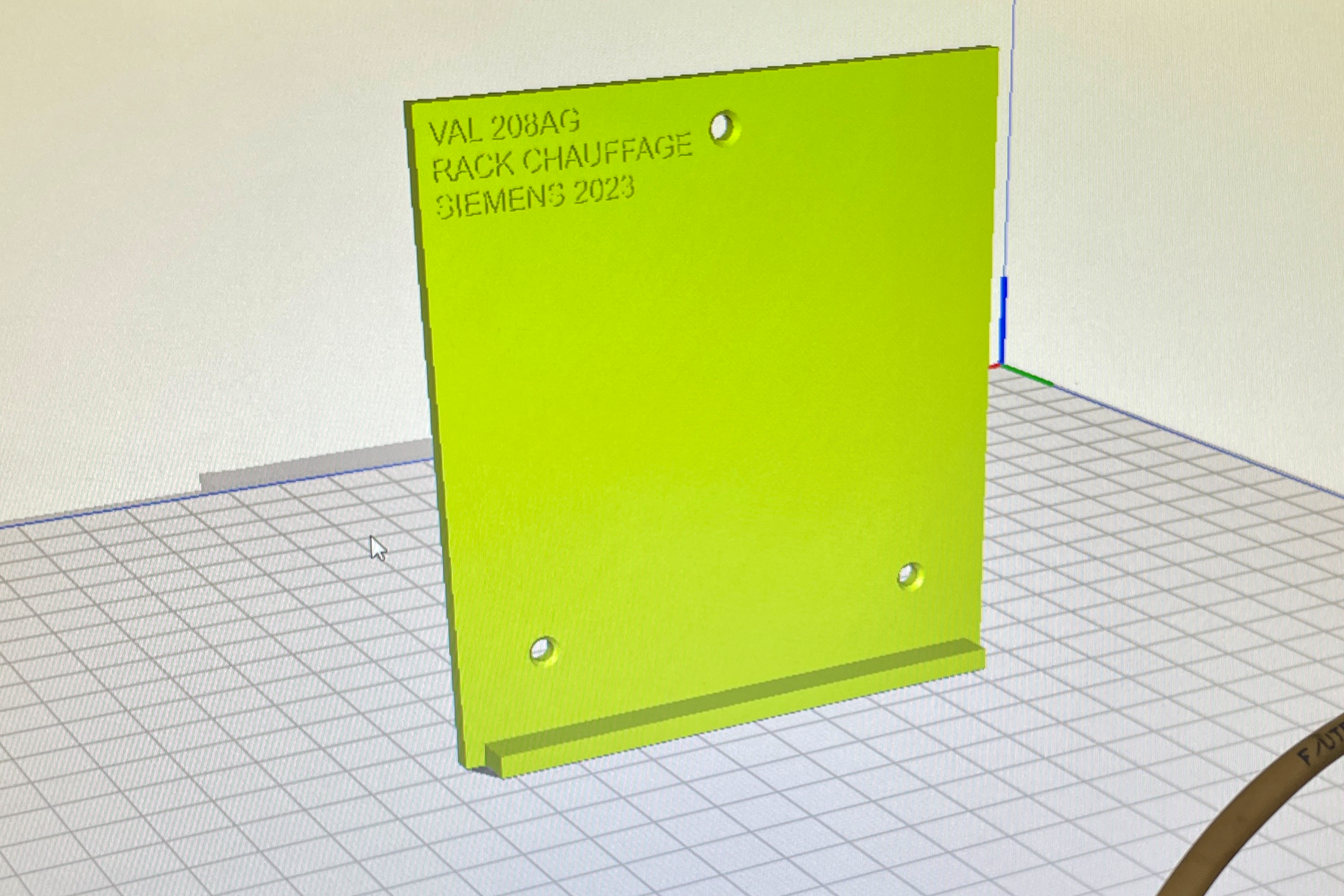

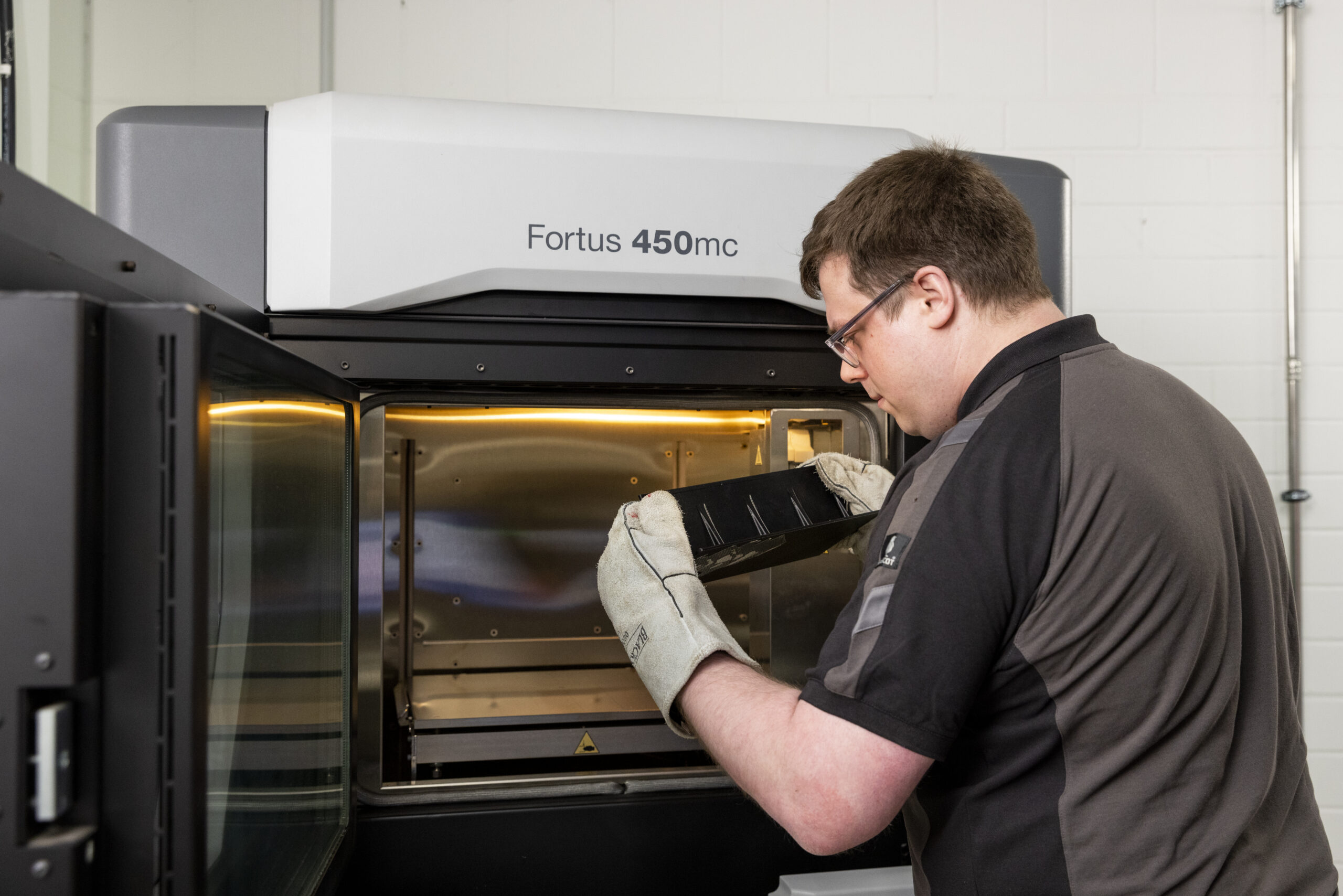

All maintenance processes can be controlled completely digitally at the Dortmund depot.

This optimizes all operations and maintenance and helps achieve up to 100% system

availability. Depot employees get their work orders and all relevant maintenance and repair

information directly on their tablets. The trains continually transmit sensor-sourced status

data to the Railigent X digital platform, where it is automatically processed. The Railigent X

application suite from Siemens Mobility analyzes this data using AI-based algorithms to

predict faults as accurately as possible and make preventive maintenance recommendations.

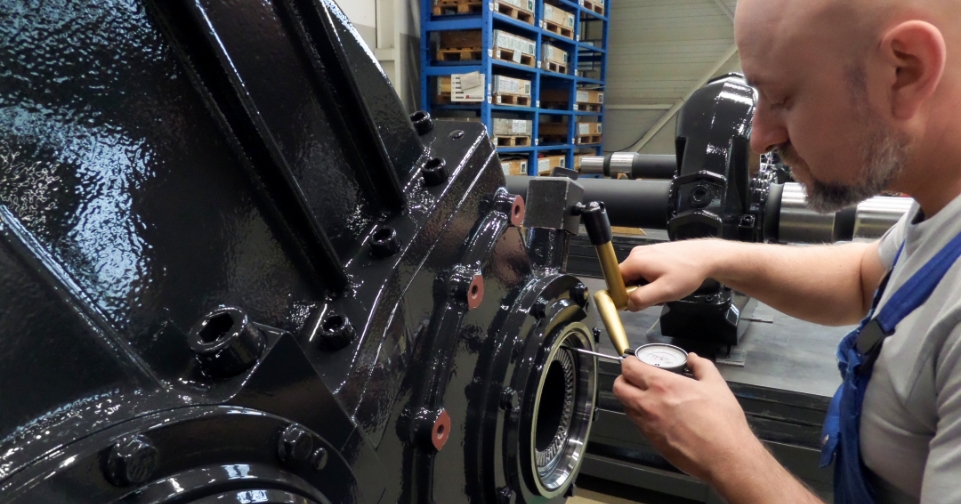

In the future, automated visual inspections will be seamlessly integrated into a train’s

operations to ensure its maximum availability and increase maintenance productivity. The

latest software solutions use advanced technologies such as computer vision, artificial

intelligence, and digital twins to inspect trains and vehicles as efficiently as possible.